Torque Limiters Couplings

Torque Limiters Couplings

The Morse Torque Limiter is a protective device that limits torque transmitted in a drive system by slipping when the torque demand exceed a preset value as a result of shock loads, overloads, or machine jams. It automatically re-engages when the overload torque has passed; no re-setting is required. It prevents machine damage and eliminates costly breakdown time.

The Original Torque Limiter

The Torque Limiter utilises spring loaded friction surfaces for its operation; slip torque is preset by adjustment of the spring force. The Torque Limiter can be used with a sprocket, gear, sheave or flange as the centre member clamped between two friction facings. Offered complete with a range of specially machined platewheels and shaft to shaft couplings, with torque range 3 - 8540 Nm.

Metric Series Torque Limiters

To extend the range of torque capability a new series of Torque Limiters is offered providing both smaller and larger sized units with a range of 1.5 to 10,000 Nm. These units are all to metric dimensions, and as with the original series are available with a roller chain coupling for shaft to shaft connection.

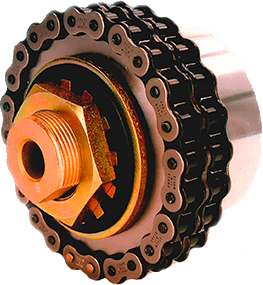

Torque Limiter combined with Roller Chain Flexible Coupling

The Torque Limiter Coupling combines overload protection with ability to connect in-line shafts. The unit consists of a standard Torque Limiter and platewheel connected to a special coupling sprocket by duplex Roller Chain. Available in eleven standard sizes, they are easy assembly units providing protection and reliability.

Torque Limiters Platewheels

Cross+Morse recommend and offer as stock items specially machined platewheels for use with Torque Limiters. Both faces of Torque Limiter Platewheels are machined to 1.6μm surface finish. Uniform surfaces and parallel faces ensure that Torque Limiters will reliably maintain correct torque release and re-engagement. For the most economical drive design, select a platewheel from the increased range of standard stock platewheels.