"M" Series Sprag Clutches

"M" Series Sprag Clutches

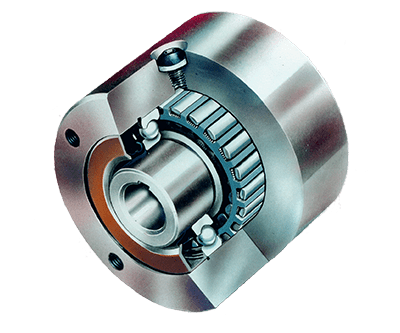

“M” series sprag clutches use precision cams made of high chrome alloy steel, hardened and honed for accurate shape. A unique finishing process ensures smooth cam surface providing uniform contact with both races for even load distribution and prolonged clutch life. High capacity bearings are used to accommodate radial and axial loads.

"M" Series Sprag Clutches

The clutches are designed to mount directly on through shafts; the torque being transmitted by a matching key provided with each stock bore; the outer race has a precision ground diameter with tapped holes on each face to enable the fitting of gears, sprockets, pulleys, etc.

Four types of clutch are offered

MG Series - Standard clutch for general overrunning, backstop and index applications, standard oil lubricated with option of grease.

MI Series - Has special sprag assembly designed for high speed indexing. Always oil filled for optimum performance.

MO Series - Fitted with labyrinth seals for minimal drag on higher speed overrun and backstop applications. Always grease lubricated.

MR Series - Utilises a special sprag cage arrangement to allow high speed overrunning of the outer race. Oil lubricated clutch suitable as a higher torque alternative to Roller Ramp clutches.

Vertical Shafts - Clutches suitable for vertical shafting can be supplied - contact Cross+Morse sales office for technical advice.

High Speed/Temperature Operation - Clutches can be provided with a patented venting system for applications subject to high temperature variation or overrunning at high speed.